A to Z of manufacturing a Royal Enfield

Timeless traditions. Sustainable innovations. And an undying passion for perfection. Watch as the minds behind the machines reveal what it takes to bring Pure Motorcycling to life, every single day.

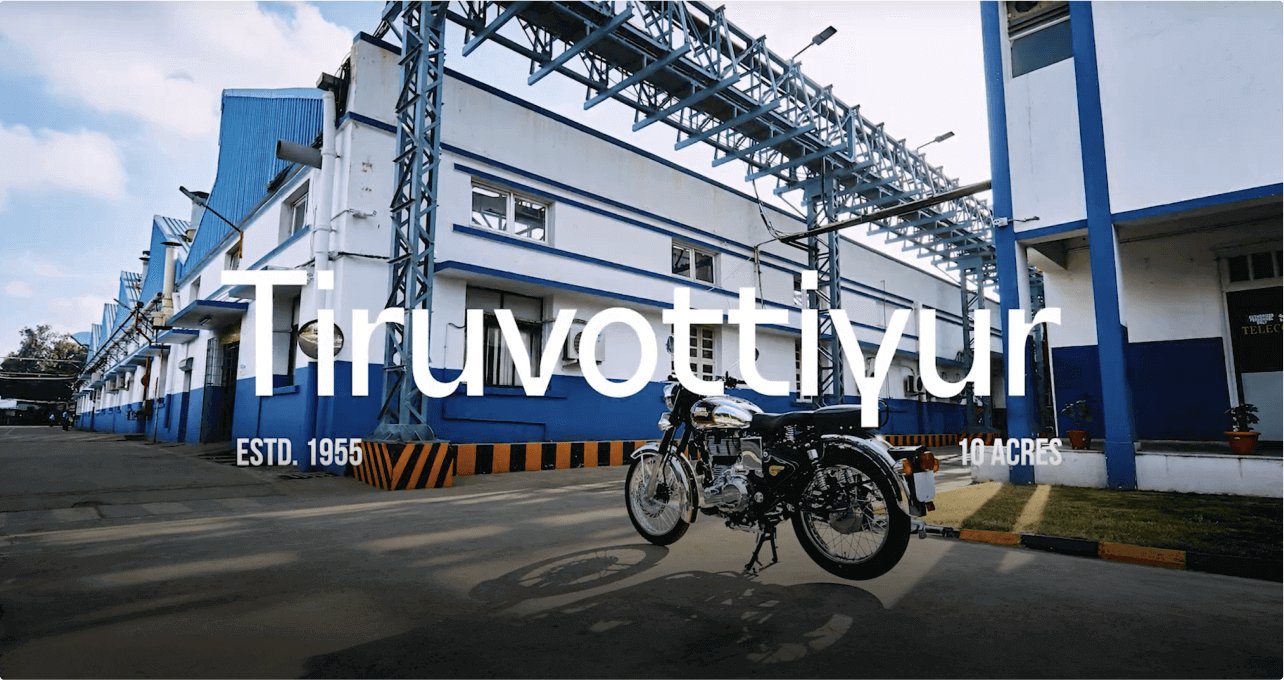

The story of Royal Enfield manufacturing